Introducing Changes to Our Filament Colors

Indeed, we're initiating a significant transformation, and consequently, our color palette will undergo a few modifications.

If you want us to ship your order using the NEW material, please let us know either on your order notes or at info@superherodiy.com (with your Order #)!

UPDATES

- Sept 3:

- BLACK: We're still printing with the old (shiny) black, let us know when you place your order if you want the new material, otherwise it will be the shiny stuff!

- WHITE: Still a bunch of the old white left, but there isn't much of a color change there.

- SILVER/GRAY: Working through the rest of the silver, will announce when the switch to gray occurs! Looking like it could be into October.

- Aug 28: We are now on the last spools of the old (shiny) black, and will continue to ship using this material until we run out. Old white and silver will take longer, likely through Sept 15.

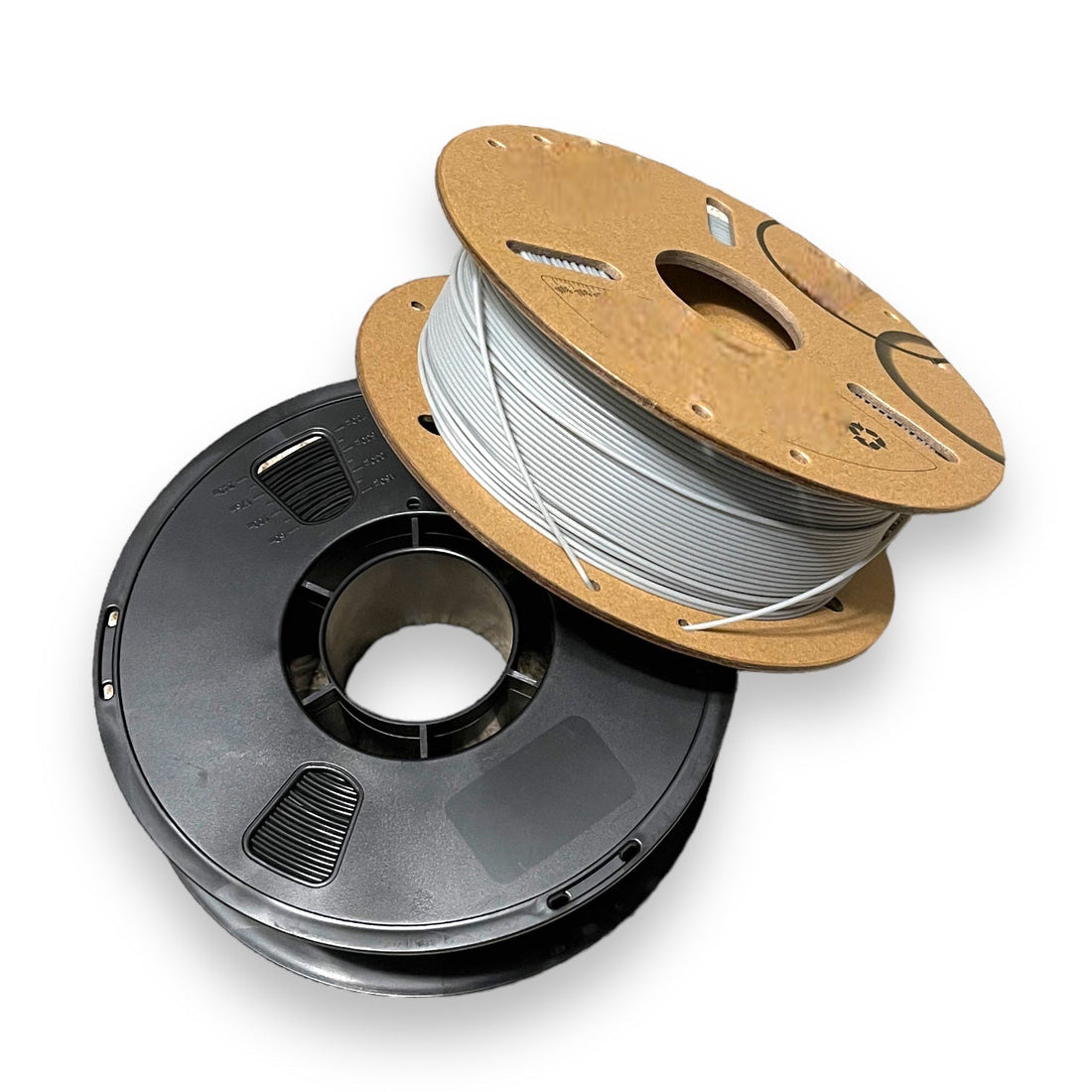

TL; DR: We're moving to cardboard spools, so white, black, and silver/gray will be a bit different after 9/1/23.

Starting August 2023, we are shifting our PLA filament suppliers for three primary colors:

- Black

- White

- Silver/Gray

The alterations in the colors are as follows:

-

Black will assume a more matte finish and will not be as dark, but more even.

-

White will transition to an off-white hue with a subtle cream undertone, appearing shinier and smoother.

-

Silver will evolve into a light gray, also boasting a smoother texture.

We anticipate completing this transition by late August 2023 and expect to be fully integrated with the new colors by September.

Any orders placed Sept 1, 2023 or later, if ordering black, white, or gray, may receive products printed with the new material as we make this transition.

In order to avoid bias, we are refraining from disclosing the names of our previous and new suppliers.

Don't get us wrong - we have thoroughly enjoyed the filament we've been using - it was notably reliable, the colors vibrant, rarely had issues such as clogging or poor bed adhesion, and it was shipped promptly from Texas. Nonetheless, we could not overlook some persistent issues that began to have significant impacts.

Our decision to change stems from two primary concerns: waste and cost.

1. Waste

We are earnestly striving to minimize our waste production.

Our previous filament supplier exclusively used ABS thermoplastic spools for their filament, showing no interest in the additional cost of employing cardboard spools. Given that we go through hundreds of spools of filament every month, we were discarding an equivalent number of plastic spools!

With no nearby ABS recycling options and exorbitant shipping costs for returning them to the manufacturer, we were left with a mounting waste problem. Attempts to resell them were futile as consumers showed little interest in used spools not directly sourced from Alibaba. Also, there were only so many craft projects we could undertake with hundreds of spools every month. Consequently, our trash bins kept swelling with black, plastic spools with no alternate use.

Frankly, it's disheartening.

Many successful filament manufacturers, like Polymaker and GreenGate3D, have transitioned to cardboard spools. The rationale behind this change is clear: it significantly reduces the volume of waste filling our landfills.

Cardboard is easily recyclable and barely impacts the performance of the spools. We already use paper cushioning for our packages, cardboard boxes, and kraft paper tape for 95% of our shipments, striving to use as few non-recyclable materials as possible.

Moreover, filament invariably unspools more smoothly from cardboard than plastic spools. This is critical in instances of filament runout, or when the printer is trying to pull it off the spool at the end of a job. On many plastic spools, the filament gets stuck, disrupting or ruining your print job which, subsequently, impacts our product delivery for customers.

The common criticism of cardboard spools is their vulnerability to humidity and degradation over time. However, being based in the relatively dry climate of Colorado, this is a negligible concern for us. While they can't bear as much weight as plastic, it's a non-issue as we only use 1kg spools.

With a scant number of manufacturers using cardboard spools (though the number is increasing), we transitioned to one that offered the most reliable material, the best color options, and the most competitive pricing. This segues into the second reason:

2. Cost

With our business growth, costs have correspondingly escalated. This necessitates passing these costs onto the customer to maintain profitability. Our most significant expense, surprisingly to some, is postage. This is precisely why returning used spools to the manufacturer was not a feasible option – shipping a 40lb box is prohibitively expensive.

Our second-largest expense is the cost of goods sold, primarily the materials we use to create our products. The prices of the PLA plastic filament we use most were continually escalating. Additionally, we were facing potential costs of increasing our trash service due to the empty spools we were discarding.

As we strive to create stronger, more durable, and more expansive display options for our customers, we have to consider the amount of material used. The quantity of material used directly influences the end pricing of our products. For instance, we recently redesigned our Combo Shelves to be stronger and slightly larger to accommodate more types of Funko Pops. We integrated additional features (and material) to prevent sagging due to weight. These changes resulted in a 30% increase in the material and time cost for each shelf, which subsequently raised the overall price.

Therefore, if we can minimize material costs, we can maintain or even reduce the price of our products. Lower overall costs mean we don't have to pass on these costs to our customers.

For the time being, we will continue to use our previous supplier(s) for most of the other colors we use. We believe that the color choices offered by cardboard-spool-suppliers are slightly off our expectations. However, as more options become available, we will reassess these opportunities.